Station ABT

Station Agro-Biotech includes several brands, such as Trema, a premium ready to drink coffee line, and Noroi, a distillery that combines traditional methods with a cold distillation process. We are proud to have partnered with this local company to implement our equipment on site.

In a nutshell

Product handled

Cans: 355mL sleek (12oz), 473 ml (16oz)

4 packs, 6 packs, 12 packs, tray x24, wrap around case x24

Our Solution in action

How Enoline helped

We offer compact equipment, and we also design implementation plans that are scalable and ergonomic. The lines installed at Noroi have optimized the flow of products, cans and cases. They were designed to integrate functionalities linked to specific equipment required by the customer.

Development of versatile production systems for a wide range of products: With the diversity of Noroi beers and ready-to-drink cocktails available on the market, the implementation of a machine capable of handling multiple formats proved crucial. Our machine enables quick and easy format changes, taking less than 8 minutes per product reference change, and is designed to be easily operated by the operator. It offers the flexibility to pack different types of product, both in terms of quantity (packs of 4, 6, 12 or in bulk) and variety (assorted packs).

The cans must be fed in separate lanes upstream, so that the machine can handle them in multi-dish format. This is usually done manually. However, thanks to our dedicated can infeed station, this automation has enabled flexible loading of different flavors for offline mix pack production.

"A real Swiss Army knife, this line! It's really flexible, it can do everything, even the mix pack."

Noroi plant manager

Solutions that really made the difference

for Noroi

The technology put in place

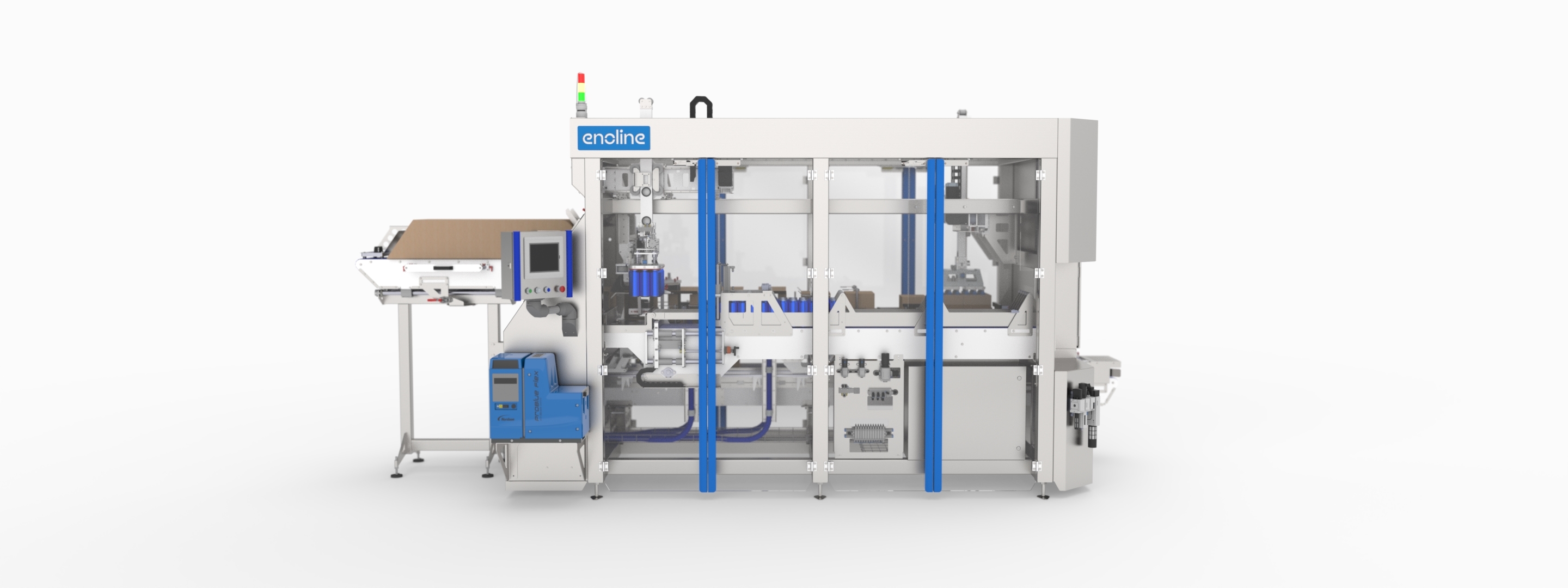

Enoline side loader

View more success stories as told by some of our dearest clients

Interested in our services?

Let's get in touch.