October 25th

The Power of Case Packing Automation

Introduction: The Evolution of Case Packing

In the world of manufacturing, case packing is a pivotal process, affecting industries across the board, from food and beverage to electronics. Traditionally, this task has relied on manual labor, but the relentless march of technology has ushered in a new era of automation solutions. The question now arises: What's the best fit for your business?

The Traditional Manual Approach

For the longest time, manufacturing landscape relied heavily on manual case packing, where the final product found its way into corrugated cartons, or 'cases,' through the toil of human hands. This manual labor was often outsourced. Surprisingly, the automation of this crucial end-of-line task has been somewhat neglected by manufacturers, possibly due to perceived capital investment challenges.

Embracing Automation: Why It Matters

Despite the initial capital investment hurdle, there are compelling reasons for manufacturers to shift towards case packing automation. Even if you already have case packing equipment in your production line, integrating new technologies and automation can elevate your setup to new heights.

Diverse Forms of Case Packing

Case packing, it turns out, comes in various forms, each suited to different needs. The choice between them depends on factors such as the product type, packaging speed, unit optimization, and product protection. Let's delve into these concepts.

Pouch Picking Case Packer

• What is it?

A case packer designed for pouches, trays, flowpacks, bags, and sachets.

• How does it work?

Utilizes delta robots for high-speed, flexible case packing.

• Why choose it?

Ideal for unstable products and high-speed requirements.

Top Load Case Packing

Top load case packing is the most widespread method, involving placing products into pre-erected American cases from the top. This method is relatively easy to transition from manual to automated processes, especially for stable products like glass bottles, cartons, pouches, and sachets.

However, when handling flexible products, the automation process demands careful consideration. While manual packing allows for easy stuffing and optimal space utilization, automation sacrifices some flexibility.

The choice of automation technology, whether industrial robots, delta robots, X-Y gantry systems, or mechanical axial movement, hinges on factors like product characteristics, speed, and packing format.

Delta robots, a relatively recent addition to case packing, bring unparalleled flexibility and speed to the table. With the ability to handle high-speed pouches, trays, flowpacks, bags, and sachets in various orientations, they closely mimic human dexterity, making them an excellent choice for flexible case packing.

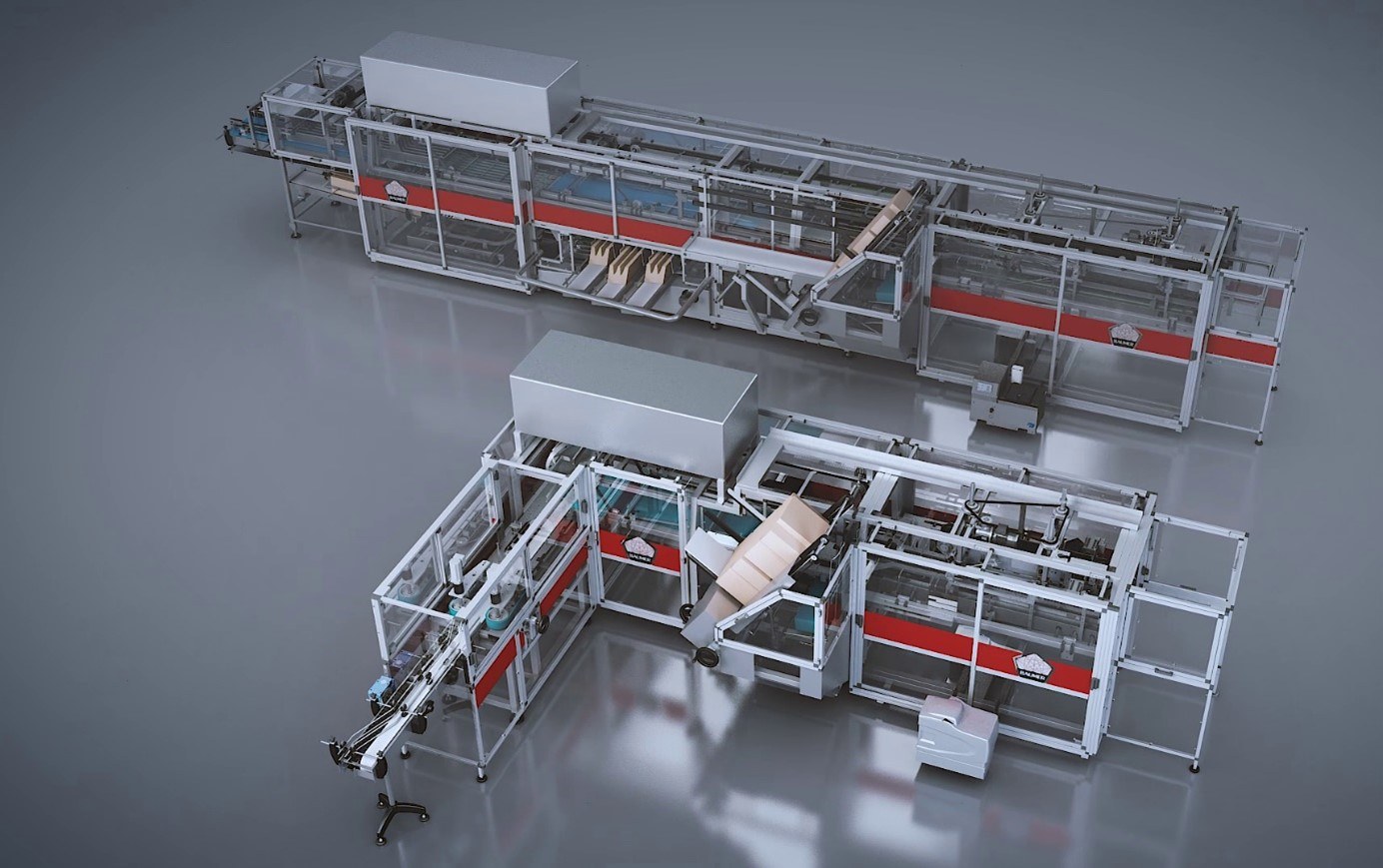

Side Load Case Packing

Side load case packing specializes in handling cartons or structured products. One remarkable feature is its monoblock nature, where the machine erects, packs, and seals cases within a compact footprint. This solution works well for low to high-speed production lines, especially when pre-forming the collation before erecting the case is necessary.

Wrap Around Case Packing

Unlike conventional American cases, wrap around case packing uses pre-cut flat sheets of corrugated blanks. This approach minimizes corrugated material usage, offering faster returns on investment and reducing the carbon footprint. Blanks wrap around pre-collated products, sealing them with hot-melt adhesives on the sides rather than the top, a boon for canned foods and beverages.

Advancing Automation: A Path to Higher Efficiency

Seasoned manufacturers in case packing automation are continually seeking ways to optimize their operations. One promising avenue is consolidating multiple primary lines into a few case packing nodes. Though advanced case packing automation comes at a premium, it promises significant returns.

With space often being a constraint for installing case packing lines, technological innovations are essential to overcome this challenge. Manufacturers now focus on maximizing "output per square meter" of factory floor space, making case packing a crucial part of the conversation. Factors like layout, speed, output, and production volumes play pivotal roles in optimizing this metric.

Speeding Up Returns: The ROI of Automation

The return on investment (ROI) in case packing automation stems from increased output and efficiency. By automating this crucial step, manufacturers can significantly boost their production rates, meeting demand faster than ever before.

In many countries, where skilled labor is often hard to find, automation addresses this challenge. Labor cost savings, reduced rejects, and decreased manual packing waste all contribute to quicker returns on investment.

The Future of Case Packing in America

As America's manufacturing landscape continues to evolve, case packing automation will play an increasingly vital role. With technology advancements and a growing focus on higher-speed production lines and efficiency, numerous opportunities await exploration.

Each case packing concept has its own unique advantages, and it falls upon manufacturers to assess which one aligns best with their needs. While the initial costs may seem daunting, the myriad benefits promise to elevate manufacturing to new heights.

Conclusion

In conclusion, the story of case packing in America is one of transformation, with automation leading the way into a future of efficiency, sustainability, and unparalleled production capabilities.

Let us find the best machine for your business !