March 23rd

Packing Machines: Types, Features, and Benefits

Are you looking for a way to improve your packaging process and increase efficiency? Look no further than packing machines! In this guide, we will cover everything you need to know about packing machines, including their types, features, and benefits.

We are here to help you chose the perfect packaging machine you need, contact us for a fast and free quote !

Introduction

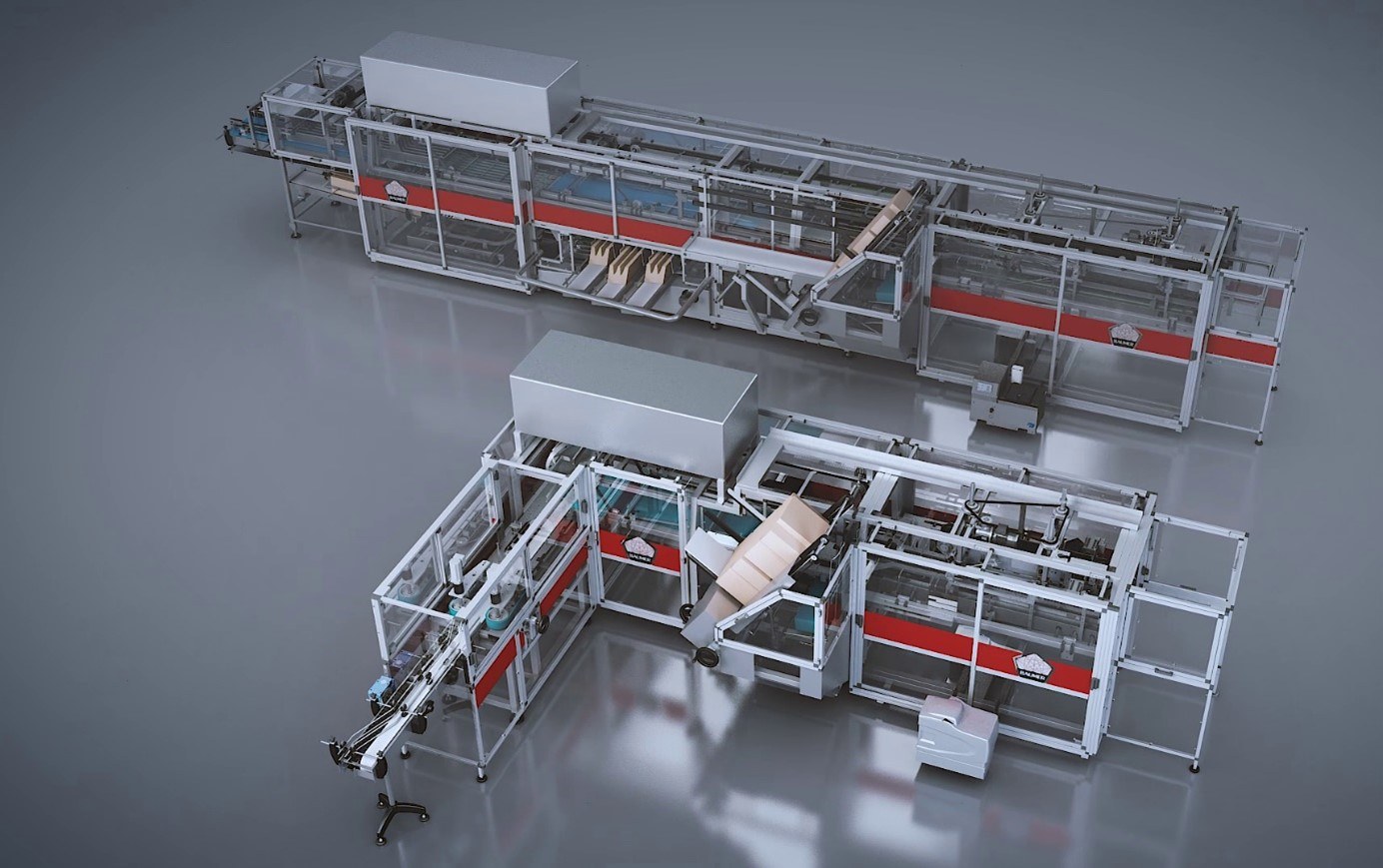

Packing machines are used to package products efficiently and effectively. They are widely used in various industries, such as food and beverage, pharmaceuticals, and cosmetics, among others. Packing machines come in different types, each designed to suit specific packaging needs. These machines are equipped with various features that make them efficient, accurate, and reliable.

Types of Packing Machines

There are several different types of packing machines available on the market, some of the most common types are:

Automatic Packing Machines : to perform various packaging tasks automatically, from filling and sealing to labeling and palletizing. These machines are equipped with sensors, motors, and controllers that enable them to function without human intervention. Automatic packing machines are suitable for high-volume production lines that require continuous operation.

Semi-Automatic Packing Machines : Semi-automatic packing machines require some human intervention during the packaging process. These machines can perform some tasks automatically, such as filling and sealing, but require manual loading and unloading of products. Semi-automatic packing machines are ideal for medium-volume production lines that require some level of flexibility.

Manual Packing Machines : Manual packing machines require full human intervention during the packaging process. These machines are suitable for small-scale production lines that require low-volume packaging.

Form Fill Seal Machines : Form fill seal machines are used to fill products into a preformed pouch or bag, then seal it. These machines can be either automatic or semi-automatic and are commonly used in the food and beverage industry.

Vacuum Packing Machines : Vacuum packing machines are used to remove air from the packaging, creating a vacuum. This type of packaging is commonly used in the food industry to extend the shelf life of products.

Shrink Wrapping Machines : Shrink wrapping machines are used to wrap products in a plastic film that shrinks when heat is applied. This type of packaging is commonly used in the cosmetic and retail industries.

Carton Sealing Machines : Carton sealing machines are used to seal cardboard cartons with tape or glue. These machines are commonly used in the shipping and logistics industry.

Stretch Wrapping Machines : Stretch wrapping machines are used to wrap pallets with stretch film to secure and protect the products during transportation. These machines are commonly used in the logistics industry.

Palletizing Machines : Palletizing machines are used to stack and organize products on pallets.

Case Packing Machines : Case packing machines are used to pack products into cases or boxes. These machines can be either automatic or semi-automatic and are commonly used in the food and beverage, pharmaceutical, and cosmetic industries.

Features of Packing Machines

Speed : Packing machines are designed to operate at high speeds, ranging from 20 to 200 packs per minute, depending on the type and model of the machine.

Accuracy : Packing machines are equipped with sensors and controllers that ensure accurate filling, sealing, and labeling of products. This ensures that each product is packaged consistently and according to the required specifications.

Efficiency : Packing machines are designed to streamline the packaging process and reduce the need for human intervention. This improves efficiency and reduces production costs.

Versatility : Packing machines can be customized to suit various packaging needs, such as different sizes and shapes of products, different types of packaging materials, and different levels of automation.

Durability : Packing machines are built to last, with high-quality materials and components that can withstand the wear and tear of continuous use.

Benefits of Packing Machines

Increased Efficiency : Packing machines can significantly increase the efficiency of the packaging process, reducing the time and labor required for packaging.

Cost Savings: Packing machines can reduce the cost of production by reducing the need for manual labor, minimizing product waste, and improving accuracy and consistency.

Improved Product Quality : Packing machines can improve the quality of products by ensuring consistent packaging, reducing the risk of contamination, and extending the shelf life of products.

Reduced Labor Costs : Packing machines can reduce the need for manual labor, minimizing the costs associated with hiring and training employees.

Enhanced Safety : Packing machines can improve safety in the workplace by reducing the risk of injury associated with manual handling of products and packaging materials.

FAQs

1. What is the difference between automatic and semi-automatic packing machines?

Automatic packing machines can perform various packaging tasks automatically, while semi-automatic packing machines require some level of human intervention during the packaging process.

2. What is the speed range of packing machines?

Packing machines can operate at speeds ranging from 20 to 200 packs per minute, depending on the type and model of the machine.

3. What is the most common type of packing machine used in the food and beverage industry?

Form fill seal machines are the most common type of packing machine used in the food and beverage industry.

4. What are the benefits of using packing machines?

Packing machines offer numerous benefits, including increased efficiency, cost savings, improved product quality, reduced labor costs, and enhanced safety.

5. Can packing machines be customized to suit specific packaging needs?

Yes, packing machines can be customized to suit various packaging needs, such as different sizes and shapes of products, different types of packaging materials, and different levels of automation.

6. How do I choose the right type of packing machine for my business?

Consider the type of product you will be packaging, the packaging materials you will be using, and the level of automation you require. Consult with a packing machine supplier for advice on the best type of machine for your specific needs.

7. Are packing machines easy to maintain?

Yes, Enoline packing machines are designed to be easy to maintain, with most models requiring regular cleaning and occasional replacement of parts.

8. Can packing machines be integrated with other production equipment?

Yes, packing machines can be integrated with other production equipment, such as conveyor belts and labeling machines, to create a fully automated packaging line.

9. How much do packing machines cost?

The cost of packing machines varies depending on the type and model of the machine, as well as its features and capabilities. It is important to consider the long-term benefits and ROI of investing in a packing machine for your business.

10. How long do packing machines last?

Packing machines are built to last and can provide years of reliable service with proper maintenance and care. The lifespan of a packing machine will depend on factors such as usage, maintenance, and the quality of the machine.

11. One example of a packing machine ?

One example of a specific type of packing machine is the water bottle packing machine. These machines are designed to efficiently pack and seal bottles of water or other beverages, often using shrink wrapping or other specialized packaging materials. With the use of pack machines like these, businesses in the beverage industry can greatly increase their packaging speed and accuracy, while also ensuring that their products are properly sealed and protected during transit

Conclusion

In conclusion, packing machines are an important investment for businesses in various industries, providing numerous benefits such as increased efficiency, cost savings, improved product quality, reduced labor costs, and enhanced safety. With the right type and model of packing machine, businesses can streamline their packaging processes and improve their bottom line.

At Enoline Solutions, we specialize in providing comprehensive packaging solutions for businesses across a wide range of industries. Whether you need a standard packing machine or a customized solution to fit your specific needs, we have the expertise and experience to deliver high-quality results. Our team of experts can work with you to identify the best packing machine for your business and provide ongoing support and maintenance to ensure that your equipment is running smoothly and efficiently. Contact us today to learn more about how we can help streamline your packaging processes and improve your bottom line.

Let us find the best packing machines for your needs