March 22nd

Enoline Solutions: Providing smart case packers

Enoline Solutions is a North American based company that specializes in designing, creating, and integrating packaging machinery lines for various sectors such as industrial, food and beverage, cosmetics, household products, and more. With a focus on smart packaging solutions, Enoline Solutions is committed to providing high-quality machines, including case packers, to businesses in North America.

We are here to help you chose the perfect packaging machine you need, contact us for a fast and free quote !

What is a Case Packer?

A case packer is a type of packaging machine that is used to pack products into cases or cartons. Case packers are often used in industries such as food and beverage, pharmaceuticals, and consumer goods. These machines automate the process of packaging products into cases, improving efficiency and reducing labor costs.

Different Types of Case Packer

There are several different types of case packers available on the market, each designed for specific applications. Some of the most common types include:

Vertical Case Packer : This type of case packer is used to package products vertically into cases or cartons. They are often used for packaging products such as bottles, cans, and jars.

Horizontal Case Packer : A horizontal case packer is used to package products horizontally into cases or cartons. They are commonly used for packaging products such as boxes, bags, and pouches.

Side Load Case Packer :A side load case packer is used to load products into cases from the side. They are commonly used for packaging products such as cans, bottles, and jars.

Top Load Case Packer : A top load case packer is used to load products into cases from the top. They are commonly used for packaging products such as bags, pouches, and boxes.

Compact Case Packer : Automated packaging systems can help to improve workplace safety by reducing the need for manual labor and minimizing the risk of injury.

Automated Case Packer : An automated case packer is a type of case packer that is fully automated, requiring minimal operator input.

Semi-Automatic Case Packer : A semi-automatic case packer requires some operator input, but still automates the process of packing products into cases.

Cartoning vs. Case Packing

Cartoning and case packing are two different packaging processes. Cartoning involves the process of packaging products into cartons, while case packing involves packaging products into cases or boxes. While the two processes are similar, they are not the same.

Robotic Case Packer

A robotic case packer is a type of case packer that uses robotic arms to load products into cases. They are highly efficient and accurate, reducing labor costs and improving productivity. Robotic case packers are commonly used in industries such as food and beverage, pharmaceuticals, and consumer goods.

How Does a Case Packer Work?

The operation of a packer depends on the type of packer being used. However, in general, a packer works by automatically loading products into cases or cartons. The machine is loaded with empty cases or cartons, and products are fed into the machine. The packer then loads the products into the cases or cartons, and the filled cases or cartons are then discharged from the machine.

Case Packer Cost

The cost of a case packer varies depending on several factors, including the type of packer, the level of automation, and the manufacturer. Prices can range from a few thousand dollars to hundreds of thousands of dollars. Robotic case packers are typically more expensive than other types of packers due to the advanced technology involved.

Three Types of Packaging

There are three main types of packaging: primary, secondary, and tertiary packaging.

Primary packaging : Primary packaging refers to the packaging that directly contains the product, such as a bottle, jar, or pouch. The primary packaging is designed to protect the product and keep it fresh.

Secondary packaging :Secondary packaging refers to the packaging that is used to group and protect the primary packages. Examples of secondary packaging include cardboard boxes, shrink wrap, and blister packs.

Tertiary packaging : Tertiary packaging refers to the packaging that is used to transport and store the products. This type of packaging is often used for bulk shipments and can include pallets, crates, and shipping containers.

Wrap Around Case Packing

Wrap around case packing is a type of packaging process that involves wrapping a cardboard sleeve around the products and then placing them in a case or carton. This type of packaging is commonly used for products such as bottles, jars, and cans. Wrap around carton packer machines can be fully automated or semi-automatic, depending on the needs of the business.

Conclusion

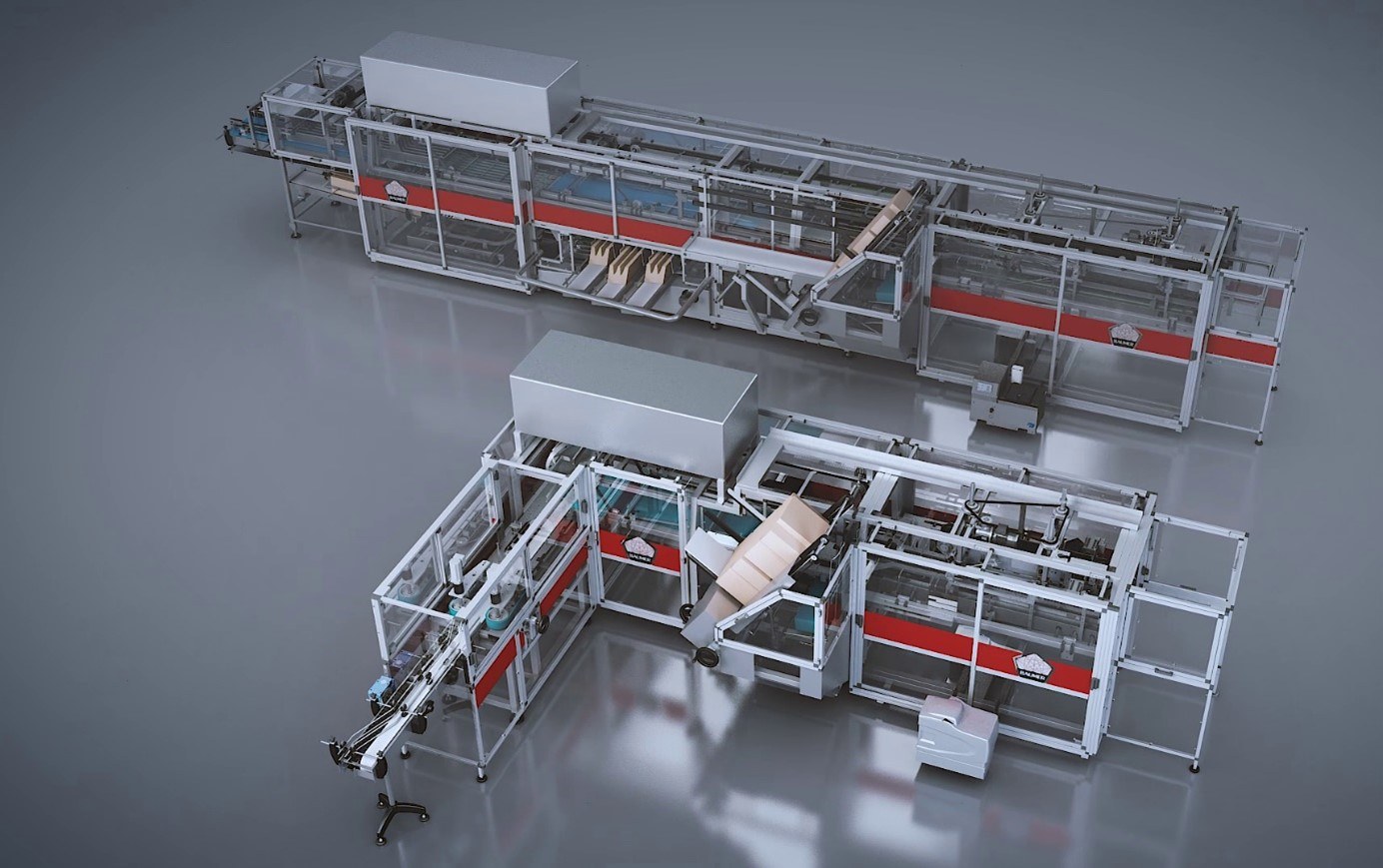

Enoline Solutions is proud to design and build some of its own machines in North America, ensuring high-quality and reliability for its customers. Whether a business needs a compact case packer for smaller products or a high-speed automated case packer for larger-scale operations, Enoline Solutions has a solution.

Enoline Solutions also offers top-notch customer service and support, helping businesses optimize their packaging processes and increase efficiency. With Enoline Solutions as a partner, businesses can trust that their packaging needs are in good hands. Trust Enoline Solutions for all your packaging needs.

Contact us and let us find for you the best case packer for your company !