June 21st

Importance of Cooling Tunnels in Food Processing Industries

Introduction

When it comes to food processing industries, the efficient and safe cooling of products plays a crucial role in maintaining their quality, freshness, and shelf life.

Cooling tunnels have emerged as an essential component in these industries, offering a controlled environment to rapidly cool down various food products. In this article, we will explore the significance of cooling tunnels and how they contribute to the success of food processing businesses.

Understanding Cooling Tunnels

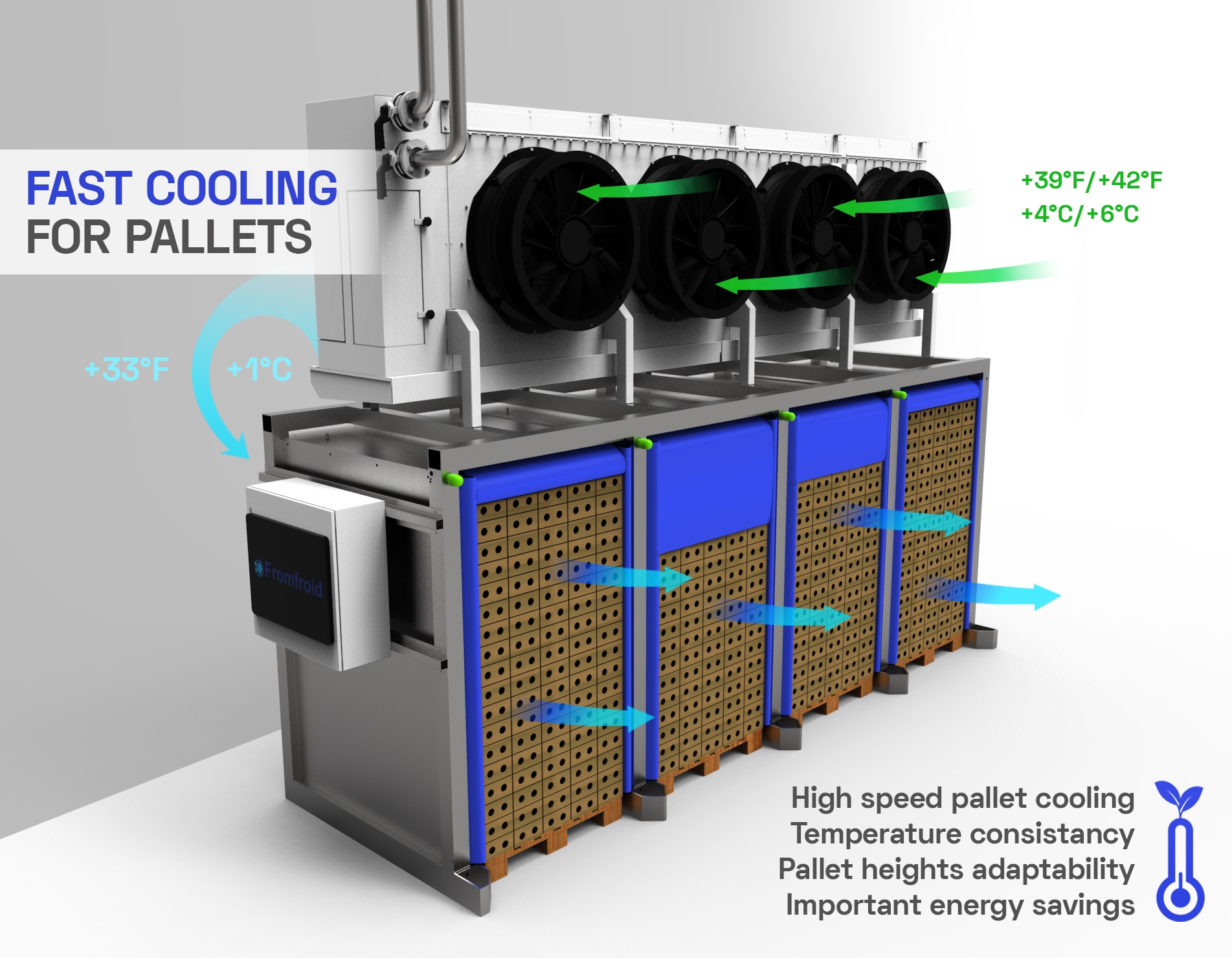

Cooling tunnels are specialized equipment used in food processing industries to rapidly cool down products after cooking, baking, or other thermal processes. These tunnels provide a controlled environment with regulated temperature, airflow, and humidity levels, ensuring that the food products cool down evenly and quickly.

The Functioning of Cooling Tunnels

Cooling tunnels work by passing the food products through a series of chambers or conveyors, where temperature-controlled air circulates around the products. The cool air absorbs the heat from the products, gradually reducing their temperature to the desired level.

This controlled cooling process helps in preventing the growth of harmful bacteria, preserving the taste, texture, and nutritional value of the food.

Key Components of Cooling Tunnels

A typical cooling tunnel consists of several important components, including:

• Conveyor belts or trays for transporting the products

• Fans and blowers for circulating the cooled air

• Evaporator coils for cooling the air

• Temperature and humidity sensors for precise control

• Insulated walls and doors to maintain the internal environment

These components work together to create an optimized cooling environment for various food products.

Types of Cooling Tunnels

There are different types of cooling tunnels available, depending on the specific needs of the food processing industry. Some common types include :

1. Continuous Cooling Tunnels:

These tunnels are designed for high-volume production lines, allowing a continuous flow of products to be cooled.

2. Batch Cooling Tunnels:

These tunnels are suitable for smaller production batches and can handle a variety of product sizes and shapes.

3. Spiral Cooling Tunnels:

Spiral tunnels utilize a vertical design, maximizing floor space efficiency while ensuring uniform cooling.

Benefits of Cooling Tunnels

Cooling tunnels offer numerous benefits to food processing industries, such as:

Enhancing Food Safety and Quality

Rapid and controlled cooling provided by these tunnels helps in reducing the risk of bacterial growth and extends the shelf life of the products. It also helps in preserving the sensory characteristics of the food, such as taste, texture, and appearance.

Increasing Productivity and Efficiency

By automating the cooling process, these tunnels save time and labor compared to manual cooling methods. They enable continuous production, ensuring a consistent output and reducing production bottlenecks.

Cooling Tunnels and Energy Consumption

Modern cooling tunnels are designed to be energy-efficient, employing technologies such as variable speed fans and energy recovery systems. These features help in optimizing energy consumption and reducing operational costs.

Maintaining Optimal Temperatures

The precise temperature control offered by cooling tunnels allows food processors to maintain specific temperature requirements for different products. This is especially crucial for heat-sensitive items, ensuring they are cooled without compromising their quality.

Cleaning and Maintenance of Cooling Tunnels

Regular cleaning and maintenance of cooling tunnels are essential to ensure food safety and prevent contamination. Proper cleaning procedures and maintenance schedules should be followed to keep the tunnels in optimal condition.

Emerging Technologies in Cooling Tunnels

The field of cooling tunnels is constantly evolving, with advancements in technology aimed at further enhancing their performance and efficiency. Some emerging technologies include intelligent temperature monitoring systems, advanced air circulation techniques, and automation integration.

Throughout the article, we have explored the significance of cooling tunnels in the food processing industry. From their functioning to the various benefits they offer, cooling tunnels play a vital role in ensuring the safety, quality, and productivity of food processing operations. As the industry continues to innovate, we can expect even more advanced cooling tunnel technologies to revolutionize the way food products are processed and preserved.

For more information on cooling tunnels and their applications, please visit our cooling solution page.

Conclusion

Cooling tunnels have become an indispensable asset in the food processing industry. Their ability to rapidly cool down products while maintaining quality and safety standards is crucial for the success of food businesses. By investing in modern cooling tunnel technologies, food processors can optimize their operations, enhance product freshness, and meet the ever-increasing demands of consumers.

Make the most of cooling tunnels to ensure your products reach consumers in the best possible condition, maintaining their taste, texture, and nutritional value.

Let us find the best cooling solution for your business !